What is volume control?

The technical term for volume control is attenuation. Volume control and attenuation are terms that are often used interchangeably in audio and mean the same thing.

Attenuation and amplification are the opposite of each other. When you amplify an audio signal you are increasing its average voltage level. A higher voltage audio signal will be louder relative to a lower voltage signal.

On the other hand, when you attenuate an audio signal you reduce its average voltage level. Thus, volume control is simply the reduction in the effective voltage of an audio signal, i.e. attenuation.

Attenuating an audio signal (i.e. reducing its voltage level) is most commonly done using a voltage divider. A potentiometer (a “pot”) is the most common type of voltage divider. Almost every time you turn a volume control knob, you are turning a voltage divider pot. But not when you’re using a Tortuga Audio preamp!

What is an LDR?

A light dependent resistor (LDR) is the marriage of a photoresistor with a light emitting diode (LED) in a small sealed package approximately the size of an M&M candy. Each LDR has 2 pairs of wires. One pair connects to the LED end while the second pair connect to the photoresistor end.

Inside the LDR, the LED shines light on the phtoresistor. The resistance of an LDR varies in proportion to the brightness of the LED which is in turn dependent on the amount of electrical current running through the LED. Increasing LED current increases the LED brightness which in turn reduces the the photoresistor resistance.

Through precise control of its LED current, LDRs can smoothly regulate resistance over a wide enough range to provide effective high performance audio volume control.

LDRs optically isolate the control circuitry from the audio signal passing through the photoresistor. The audio signal only encounters a variable resistance that is regulated by photons (i.e. light) and not electrons.

Tortuga Audio preamps utilize LDRs to control volume (i.e. to attenuate the audio signal).

Why LDRs for volume control?

We use LDRs because the resulting subjective sound quality is amazing. Adjectives like clear, open, unveiled, articulate, and uncolored all apply to the LDR. All while maintaining excellent bass and overall dynamics even in a passive preamp.

If LDRs are so great why then why don’t all preamps use LDRs? A reasonable question. Here’s why not.

First, LDRs are notoriously difficult to use for volume control. They are inherently nonlinear which means they are difficult to control accurately over the wide range of resistance needed for effective volume control.

Secondly, the performance curve of individual LDRs are not consistent even within the same make and model from the same production batch. Moreover, their performance curves may even drift slightly over time.

Last but not least, LDRs have higher distortion characteristics than most other alternatives although not enough that it really matters subjectively (the distortion is well below human detectable levels).

For all the above reasons most audio designers have avoided taking on the challenge of using LDRs.

Tortuga Audio took on this challenge over 10 years ago and has not looked back. We overcame these technical challenges. We are now on our 5th generation LDR preamp control technology.

How do LDRs control volume?

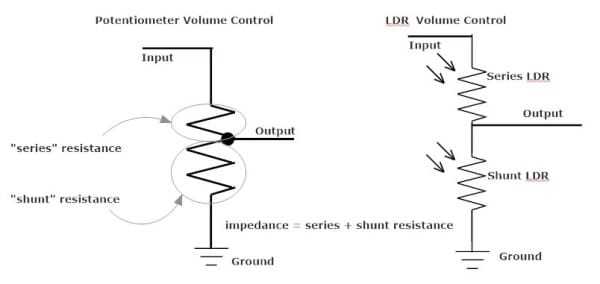

Volume control with LDRs is conceptually similar to how a conventional potentiometer works so lets look first at how a potentiometer (“pot”) is used for volume control.

Pots that are used for volume control typically have a fixed resistance between 10k and 100k ohms. The audio input signal connects at one end of this fixed resistance and the other end is connected to ground. Thus the input signal sees a fixed resistance (impedance). The output signal from the pot is a third connection or what’s referred to as the pot’s “wiper” which slides along the pot’s fixed resistor as the pot’s shaft is turned. The wiper carries the output signal of the pot. This is shown in the diagram below.

Here’s what’s going on as we dive a little deeper. The variable resistance above the wiper is the series resistance (Rseries) and the variable resistance below the wiper is the shunt resistance (Rshunt). The sum of Rseries plus Rshunt equals the rated fixed impedance (10k, 50k, 100k etc. ) of the pot.

The Resistance Ratio (or “Ratio”) is defined by the simple formula: Ratio = Rshunt/(Rshunt + Rseries). This Ratio also happens to be the voltage ratio of Vout divided by Vin such that Vout = Vin x Ratio. A pot’s attenuation level at any point along the wiper can be expressed in decibels which is defined as 20 x log(Ratio). Putting all this together your arrive at dB = 20 x log (Vout/Vin) where Ratio = Vout/Vin = Rshunt/(Rseries + Rshunt). These are the basic governing equations of most volume control.

Thus, when Rseries is zero the volume is maximum (no attenuation) and when Rshunt is zero the volume is zero (maximum attenuation). In between the volume goes from zero to maximum as the pot shaft is turned.

Volume control with LDRs works basically the same way except that with LDRs the RSeries and RShunt resistance levels can be controlled completely independent of each other. Once the LDRs are calibrated, a microcontroller can control each independent LDR to achieve the resistance ratios that correspond to specific dB attenuation levels over a wide range of volume control. While a pot does this mechanically, the resistance levels of both the series and shunt LDRs must be done electronically and may not involve any mechanical elements at all.

Repeatable and reliable electronic control of LDRs is at the core of Tortuga Audio’s LDR volume control technology.

Additional LDR documentation

LDR Input & Output Impedance